top of page

Welding Jig Proof Of Concept

|  |

|  |

Our Intro

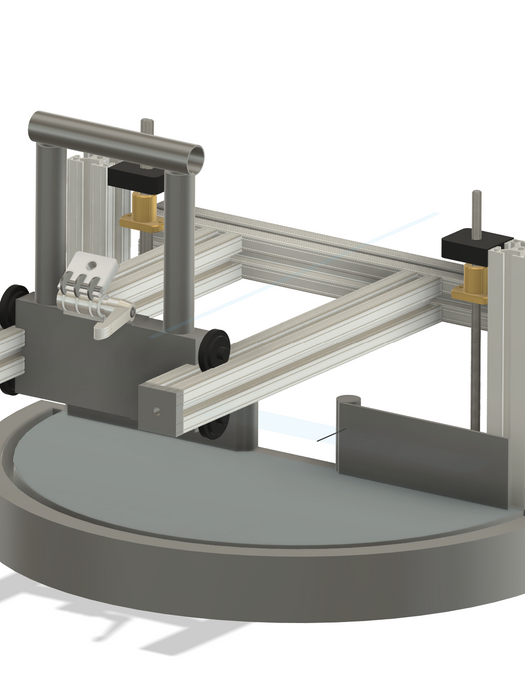

We built a proof-of-concept jig to test whether it could be developed into a commercial tool for making it easier to weld sections at different angles. The jig works by using two adjustable angle plates, to which material sections can be clamped together. The welder is mounted on a straight-line track, allowing for repeatable and accurate welds, which helps reduce production time and cost. Proof-of-concept models are not as refined as commercial prototypes; they are meant to quickly and affordably test ideas before investing in full-scale development. Our jig was constructed from mild steel for durability and was fully welded together. It took three rounds of prototyping to reach the version you see above—starting with a cardboard iteration, followed by one made of wood, before transitioning to a steel build. In the end, our testing showed that a refined, commercial version of this jig would indeed be feasible to produce.

|  |

|  |

CAD Design

For the CAD design, we explored different ways to make the jig more versatile and user-friendly. One idea was to use T-slots for the base, allowing other jigs and fittings to be easily added or adjusted as needed. This would make the system more modular and adaptable for different welding setups. We also incorporated a numbering system along the sidewall to enable quick and precise measurements, improving efficiency and repeatability. These design considerations aimed to enhance the jig’s functionality while keeping it practical for real-world use.

Manufacture of First Prototype

For the first prototype, we laser-cut the design from cardboard and assembled it to test the overall dimensions and fit of the components. This allowed us to quickly and cost-effectively evaluate the basic layout before committing to more durable materials. The goal was to ensure that key elements, such as the clamping positions and angle adjustments, were correctly sized and positioned. Using a lightweight material like cardboard made it easy to make adjustments before moving on to the next iteration.

|  |

|  |

Manufacture of Second Prototype

For the second prototype, we used wood to create a more rigid and durable version of the design. Building on the lessons learned from the cardboard prototype, we refined the dimensions and improved the structural layout to better simulate the final product. This version allowed us to test the clamping system more effectively and evaluate how the jig would handle real-world use. The wooden prototype also provided a better sense of weight and stability, helping us identify any necessary adjustments before transitioning to the proof-of-concept steel version.

|   |

|  |

Now, you've seen one our projects, but what about yours?

Get In Touch

today by clicking 'Get a Quote' at the top of the page.

bottom of page